The fully automatic brick palletizing machine will cover all the traditional brick factory palletizing market. If it does not develop and innovate, it will be eliminated by the society! This is not an exaggeration, but the development of society is inevitable! With the rapid development of society and economy, the creation of "high-tech first, energy saving and emission reduction, cleaning and environmental protection" brick and tile factories has become a new trend of industrial development. In order to follow the rapid development of the trend, it is necessary to automate the brick and tile factories. Technology and environmental protection come first! So the status of the brick yard machine in the brick factory is particularly prominent, and what benefits does it bring? The reason why it is recommended to use fully automatic code bricks is: to save manpower and save costs!

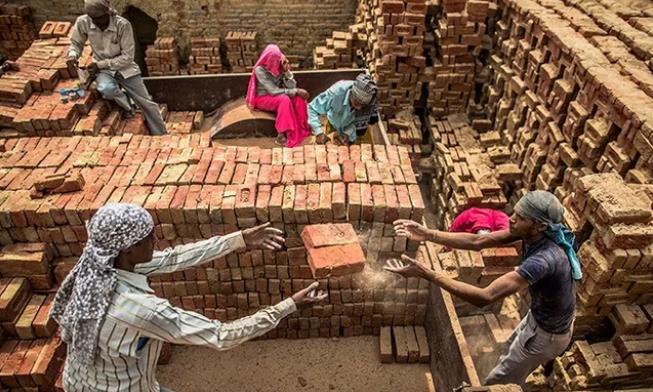

Due to the convenience of transportation and convenient use, the bricks need to be palletized after being produced by the manufacturer. In traditional production, the bricks should be palletized by manpower after being formed. Even if the brick yard workers work more than 10 hours a day, they not only need to pay a few thousand yuan in labor costs, but also this method has low efficiency and high risk. The work that used to require more than 10 workers to complete can now be completed by two people. One person is in charge of operating the equipment and the other is in charge of loading the bricks with the forklift. This year, if you save this labor cost, you can buy a yard brick! Under normal maintenance, their brick yard machine can be used for more than ten years; in the first year, the manufacturer will pay back the money from buying the machine, and in the next ten years, it will be making money for the manufacturers, and professional Service does not stop!

If the brick factory is relatively large, 3-4 people are needed, and it is only one more professional PET plastic-steel belt packaging person! If it is a fully automatic production line, the packer can also be omitted and replaced directly by a skilled professional equipment operator. The staff responsible for taking care of the machine can help pack the pack, so three people can still complete it! If only two people are used, the packaging of bricks can also be done automatically with an automatic rotary baler or arrow-piercing baler. This is the standard configuration that a modern brick factory should have!

Contact: Jenfyfu

Phone: 008615375766222

E-mail: okblockmachine@gmail.com

Add: Taoyuan Industrial Zone, Fengzhou Town, Quanzhou City, Fujian Province, China Mainland.